Granite Steps: The Technical Advantage for Modern Construction & Design

- navinsethi

- Sep 11

- 3 min read

When it comes to durability and aesthetics in architectural projects, granite steps / treads risers stand out as a premium solution. Beyond their natural beauty, granite and other natural stones possess unique geological, mechanical, and functional properties that make them superior to conventional materials like concrete or ceramic tiles.

At Aravali India Marbles & Granites, we bring over 25 years of expertise in quarrying, processing, and exporting premium natural stones, ensuring that every granite step meets global construction standards for strength, precision, and finish.

🔹 Key Technical Advantages of Granite Steps

1. Exceptional Compressive Strength

Granite is primarily composed of quartz, feldspar, and mica, giving it a compressive strength ranging from 130–250 MPa. This makes granite steps capable of withstanding heavy loads and foot traffic in high-usage spaces like commercial complexes, airports, and public buildings.

2. Hardness & Wear Resistance

With a Mohs hardness of 6–7, granite is resistant to scratches and abrasion. This makes it highly suitable for external staircases, outdoor landscaping steps, and pool surrounds, where high durability is a must.

3. Weather & Thermal Resistance

Granite steps have a low water absorption rate (0.2–0.4%), ensuring excellent resistance to freeze–thaw cycles, rain, and extreme temperatures. Unlike engineered materials, granite maintains its structural integrity in both hot desert climates and freezing European winters.

4. Surface Finishing for Functionality

Granite can be processed in multiple finishes to suit safety and design requirements:

Polished – reflective, elegant, suited for interiors.

Honed – smooth, matte, ideal for subtle interiors.

Flamed – rough, slip-resistant, perfect for exteriors.

Leathered – textured yet refined, adds grip and unique aesthetics.

Bush-hammered – rugged and anti-slip, often used in outdoor staircases.

These finishes allow tailored functional performance, ensuring steps meet slip resistance values (SRV/R Values) required for global building codes.

5. Custom Fabrication Options

Granite steps can be manufactured with bullnose, half-round, chamfered, or square edges, depending on safety and aesthetic requirements. CNC processing allows precision cuts for custom lengths, thicknesses, and edge profiles, enabling easy integration into both traditional and modern designs.

6. Low Lifecycle Cost

While granite may have a higher initial cost compared to concrete or ceramic, its lifespan of 50+ years with minimal maintenance makes it a cost-effective investment. The stone requires only occasional sealing and cleaning, lowering long-term operational costs for commercial projects.

7. Sustainability Factor

As a 100% natural material, granite has a lower embodied energy compared to many artificial materials. When quarried and processed responsibly, it supports sustainable construction practices, making it an ideal choice for LEED-certified and green building projects.

🔹 Applications of Granite Steps

Residential Projects – luxury villas, modern apartments, indoor staircases.

Commercial Projects – hotels, malls, airports, offices.

Public Infrastructure – railway stations, government buildings, museums.

Landscape Architecture – garden pathways, pool surrounds, terraces, and outdoor amphitheaters.

🔹 Most Demanding Granite steps risers from our factory:

Jhansi Red Granite Steps Risers / Treads

New Imperial Red Granite Steps Risers / Treads

Black Galaxy Granite Steps Risers / Treads

Absolute Black Granite Steps Risers / Treads

Verde Guatemala / Green Marble Steps Risers / Treads

Rosy Pink Granite Steps Risers / Treads

Colonial White Granite Steps Risers / Treads

Crystal Yellow Granite Steps Risers / Treads

🔹 Why Choose Aravali India Marbles & Granites for Granite Steps?

Advanced Processing Facilities – multi-disc cutters, automated polishing lines.

Export-Grade Packaging – ISPM-15 certified wooden crates, seaworthy pallets ensuring safe global deliveries.

Bulk Supply Capacity – MOQ: one container (~27 MT / 500 sqm of steps risers).

Global Reach – long-term supply partnerships across USA, Europe, Middle East, and Latin America.

Custom Orders – we deliver cut-to-size steps, treads, risers, and finished profiles as per architectural drawings.

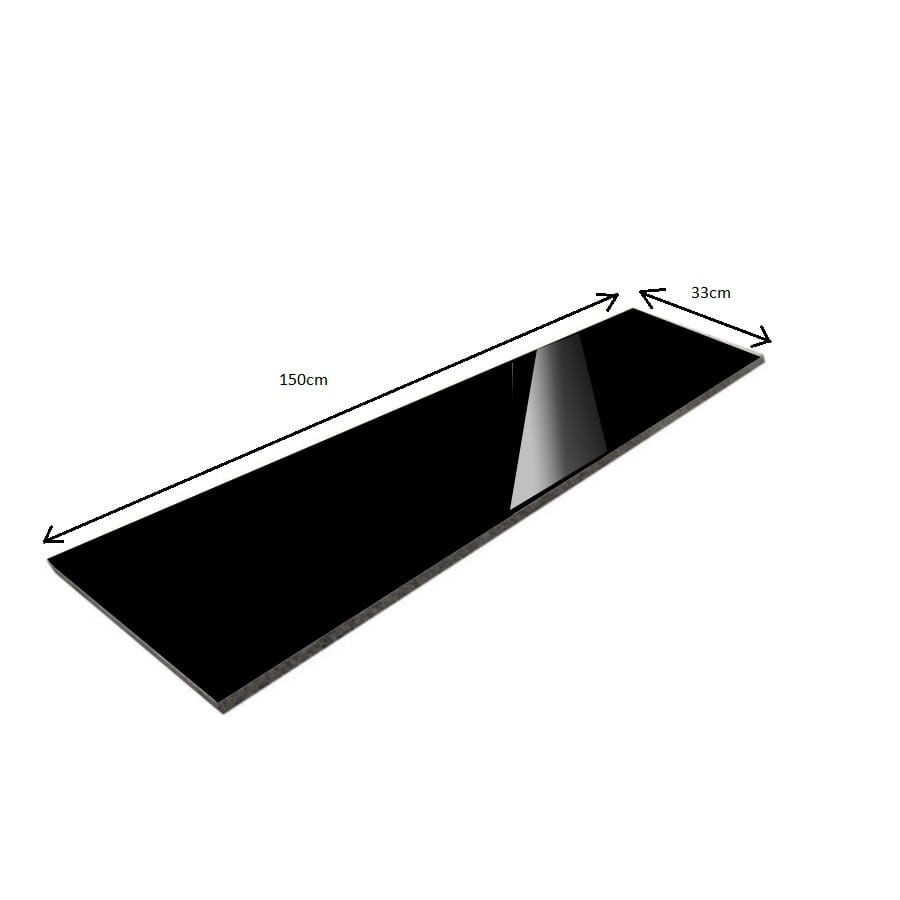

Stairs Specifications:

Steps:

110 cm to 160 cm X 33 cm X 2 / 3 / 4 cm thick

Finishes: Top polished, with edges bevelled and polished, (anti-slip line, with flamed bush hammered sandblasted processing)

Risers:

110 cm to 160 cm X 14 / 15 / 16 cm X 2 cm thick

Finishes: Only top polished, others sawn cut, visible edge polished.

Steps Edge: Half / Full Bullnose, Eased, or as your requirements.

🔹 Conclusion

Granite steps are more than just an aesthetic upgrade — they are a technical solution for strength, safety, and sustainability in modern construction. With properties like high compressive strength, weather resistance, low maintenance, and customizable finishes, granite remains the preferred choice for high-traffic staircases and outdoor applications.

At Aravali India Marbles & Granites, we combine geological expertise, modern fabrication technology, and global export experience to supply premium granite steps tailored to the needs of bulk importers, contractors, and architects.

Comments